Strength and Technology

Strength and Technology

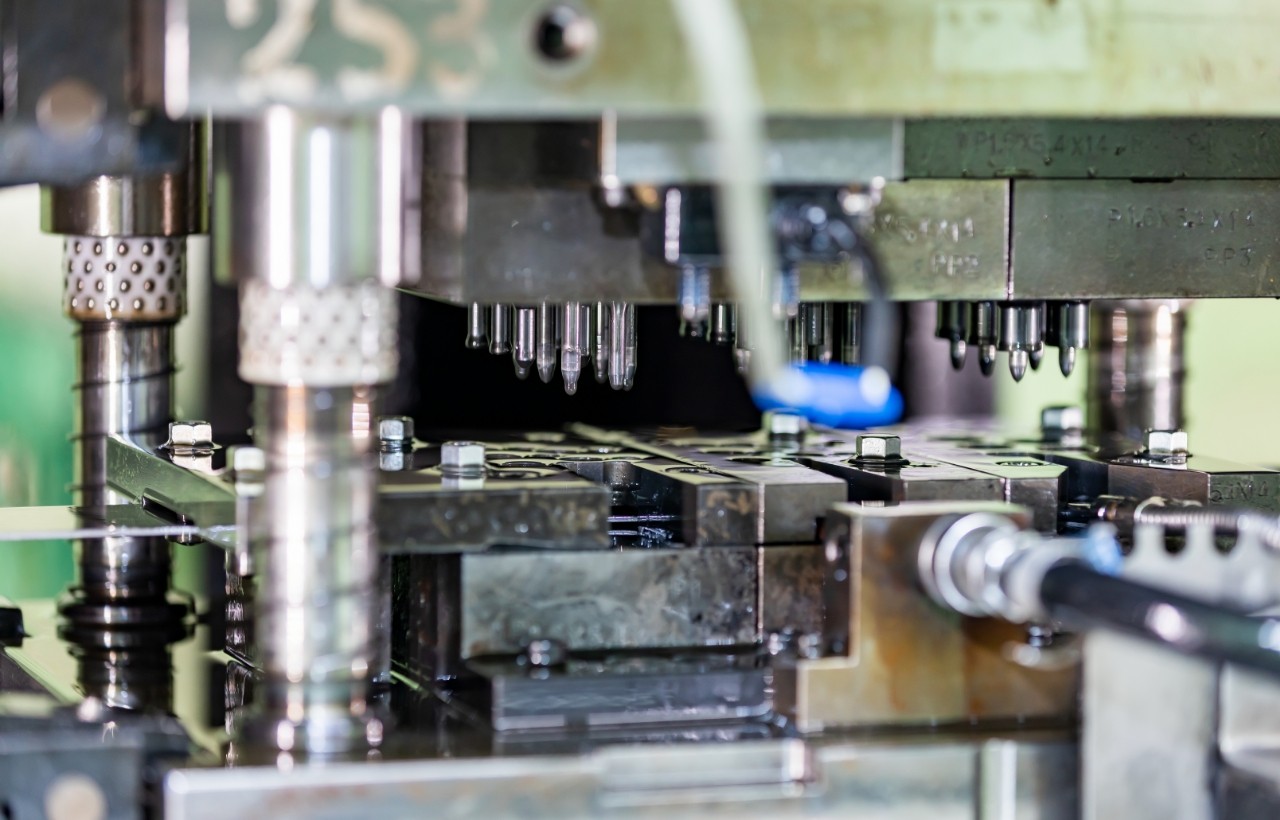

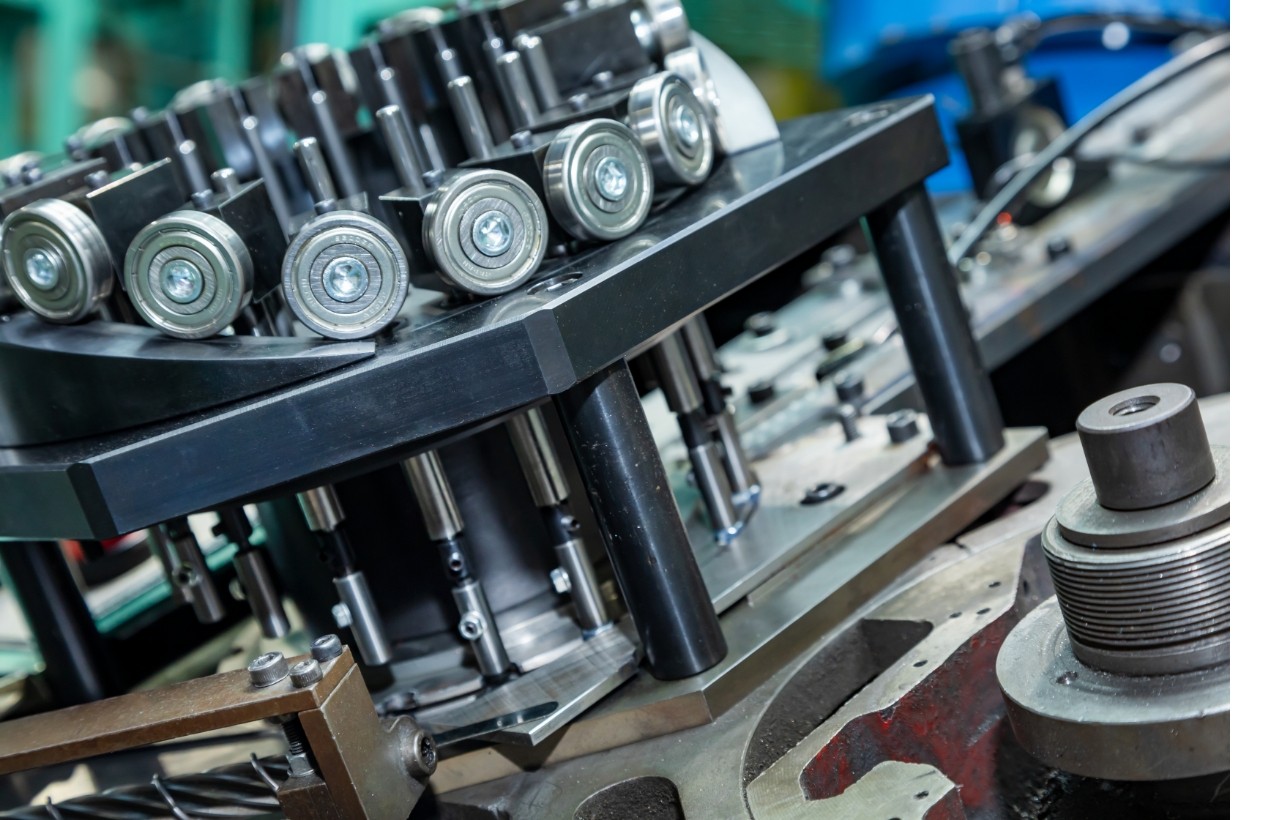

Constructed a highly technical processing method using a press machine

High-precision mass production technology

Technology for high precision and mass production

Realization of high-precision processing of cut products by using high-precision molds

Consistent guarantee from mold design to manufacturing

Repeatable and precise technology

Thorough atmosphere management and high-precision machine tools have realized mold processing technology in micron units.This technology not only enables the manufacture of precision molds, but also provides an integrated guarantee from mold design and manufacturing to the manufacture of jigs and tools.

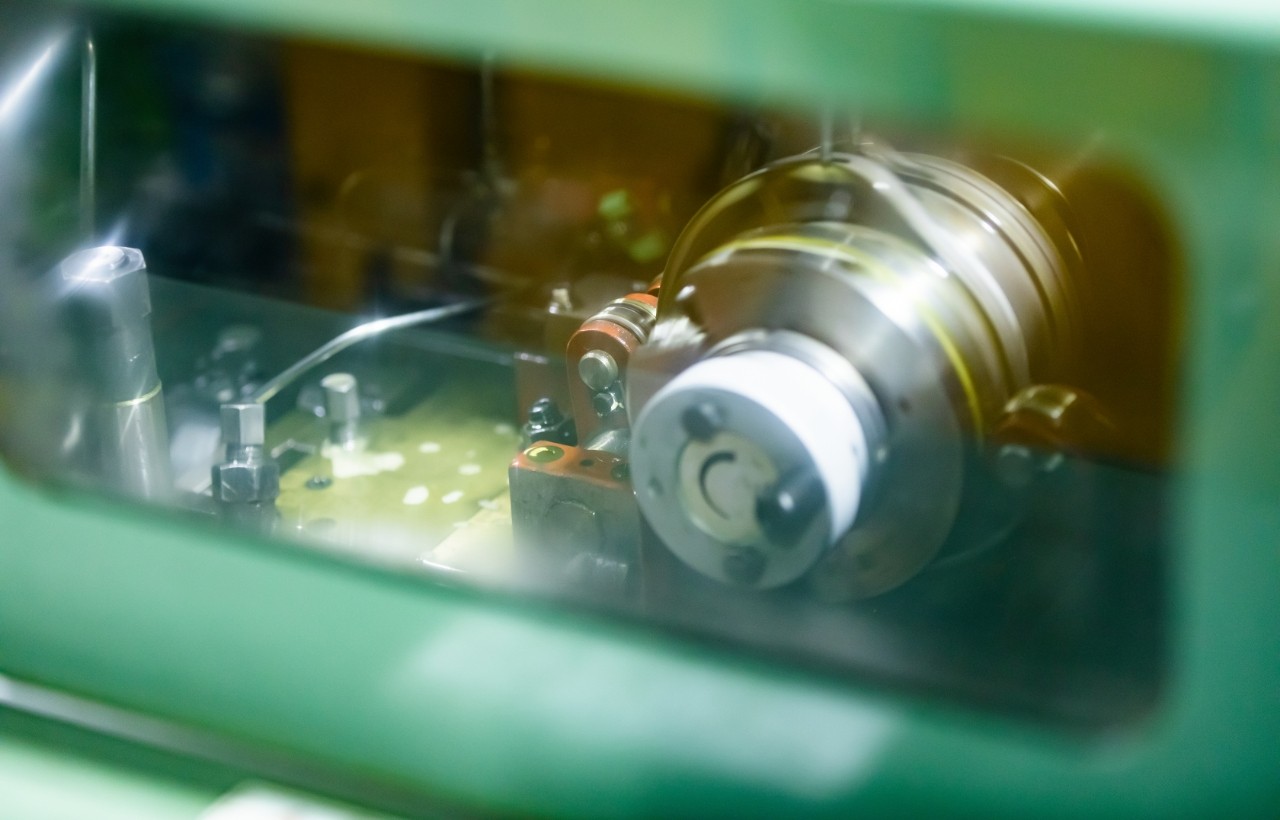

Cutting edge mold heading of Drill screw

One and only design for sharpness only available with us

Based on our original mold design, we have developed a new concept drill screw that has a suppression effect on delayed fracture and fatigue tests.Depending on the various building parts and applications, the base thickness can be used in a wide range from thin to thick, realizing sharpness not found in other companies.

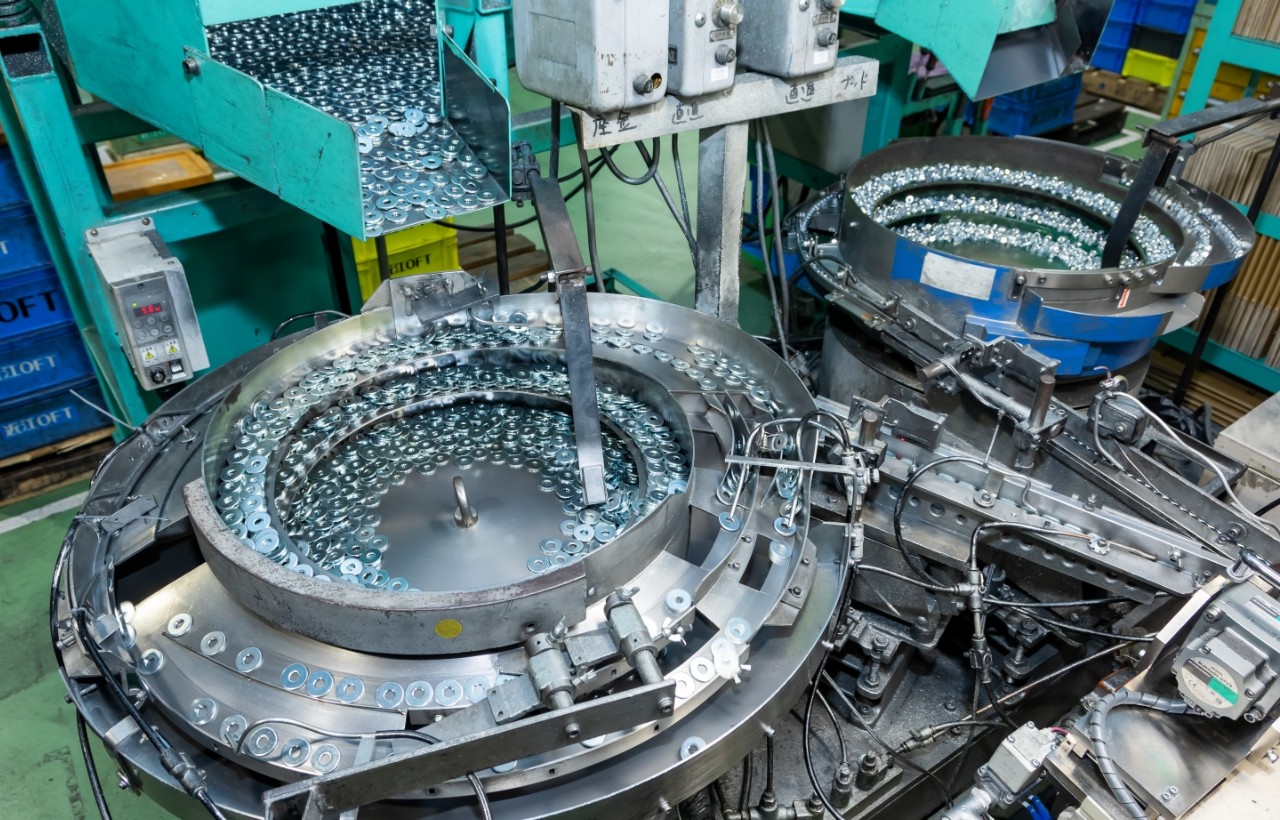

WITH NUT®

Integrating nuts and washers to contribute to manufacturing sites

It is a patented technology that integrates washers such as conical washers, corrugated spring washers (TWOLOCK), flat washers, and toothed washers by caulking them into nuts.Which contributes to reducing man-hours and time at manufacturing sites

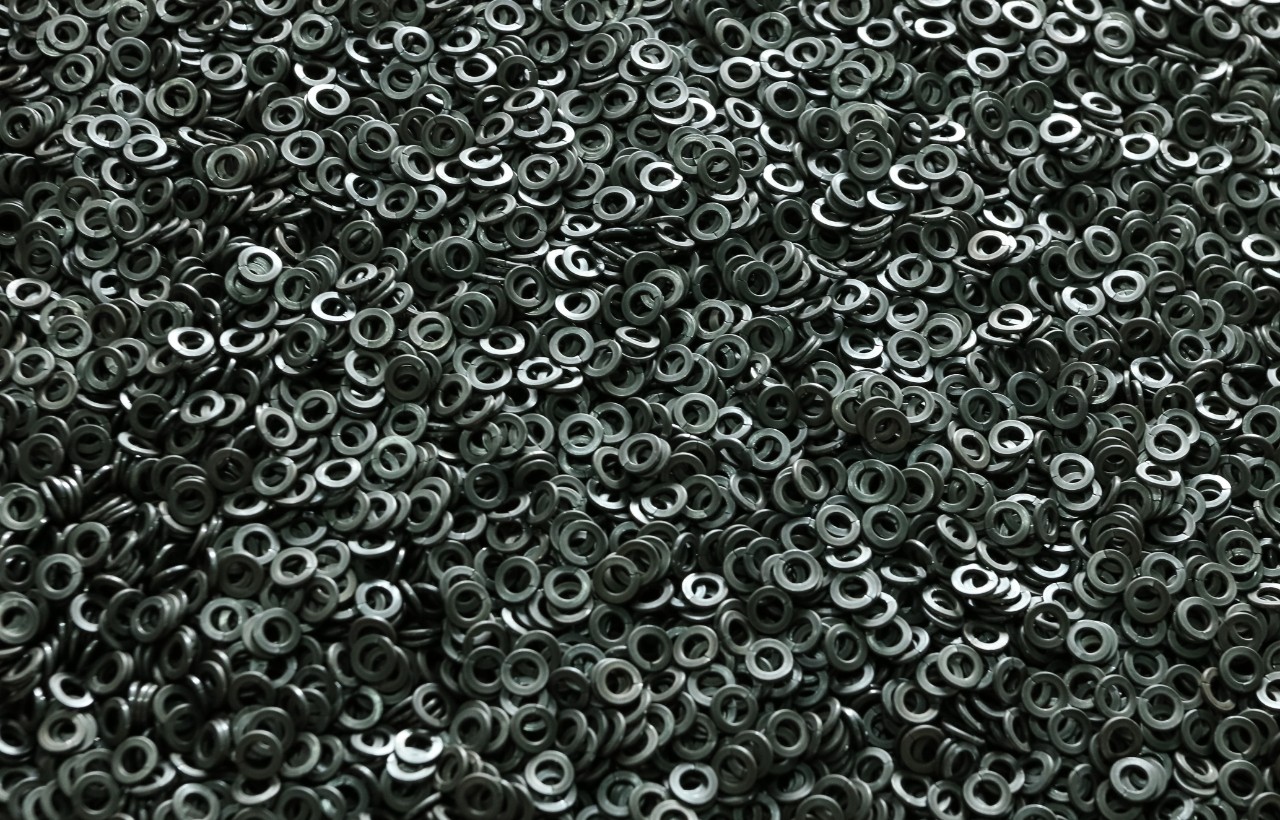

TWOLOCK

High anti-loosening effect

Due to its shape characteristics, it has superior spring reaction force compared to spring washers (SW) and is used in parts that require a high anti-loosening effect.In addition, it also contributes to weight reduction since the plate is thin. Furthermore we contribute to short delivery time and low cost by in-line from wire drawing to molding.

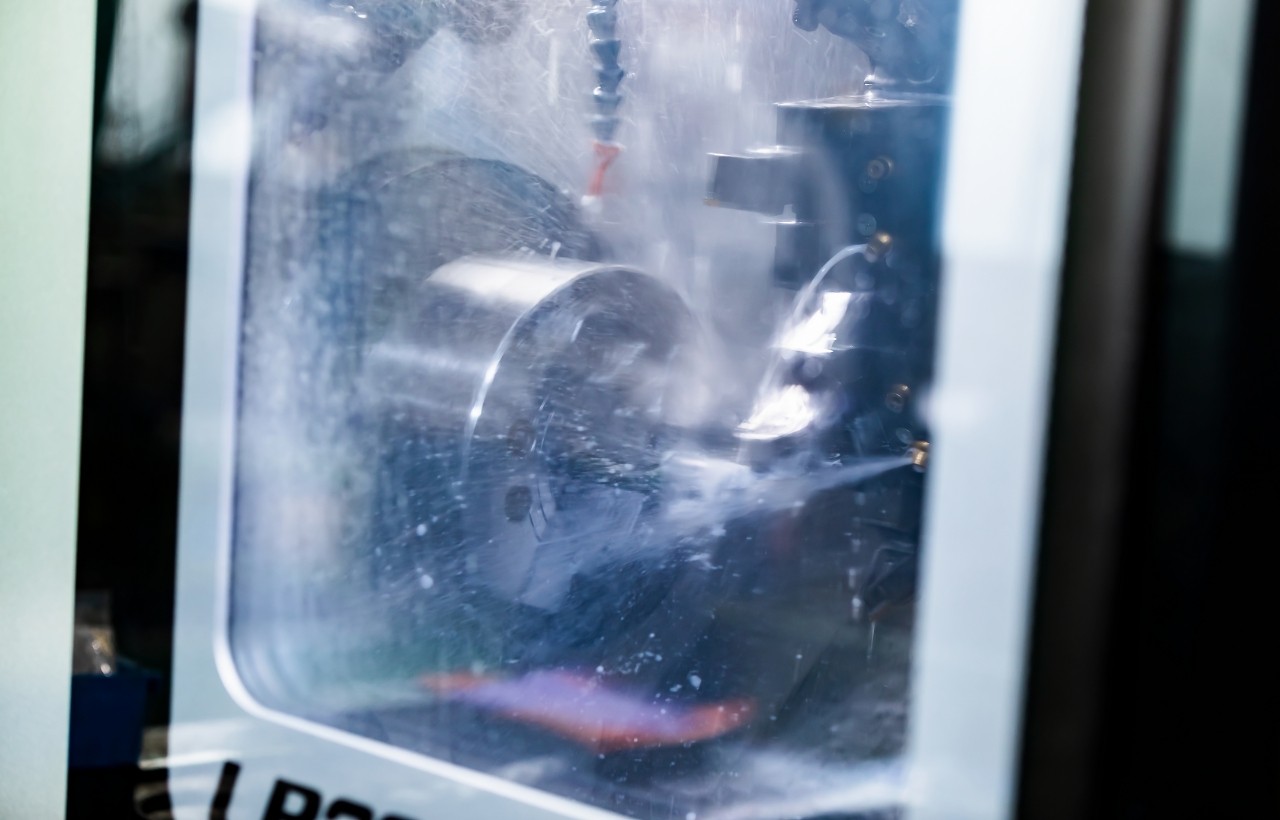

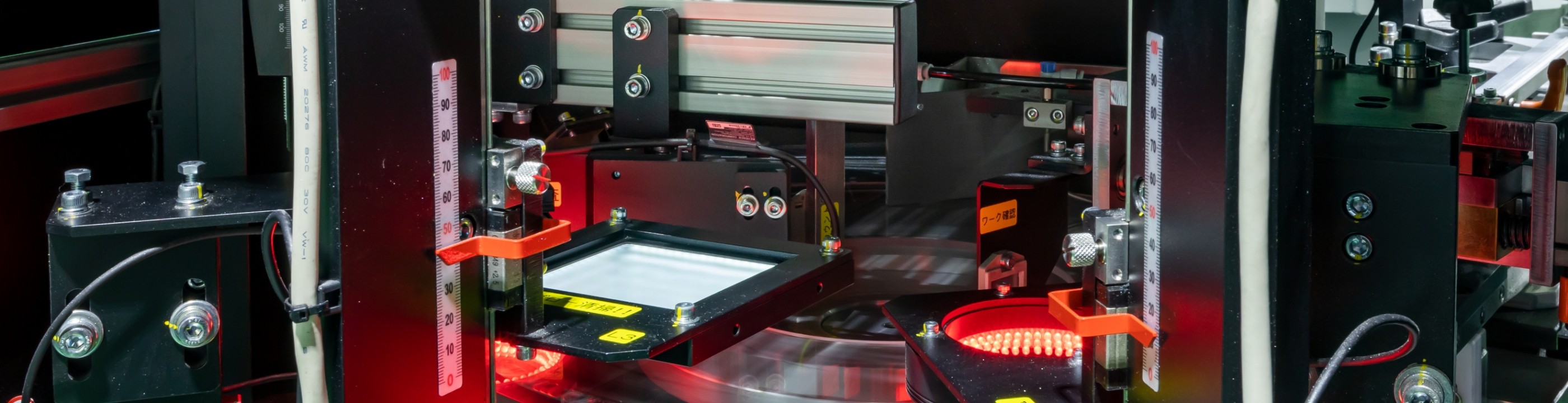

Established 100% guarantee system

Reliable inspection by optical sorting line

In order to always provide high-quality and reliable products, we have established a thorough inspection process such as an optical sorting line. We also provide high-precision manufacturing equipments. In order to always provide high-quality and reliable products, we have established a thorough inspection process such as an optical sorting line. We also provide high-precision manufacturing equipments.

Equipment

- Press Machine 20t-400t

- Total 22

- Nut Former

- Total 4

- Nut Washer Embedded Machine

- Total 10

- Rolling Machine

- Total 8

- Shank Slotter

- Total 3

- Electrical discharge Machine

- Total 4

- Cylindrical Grinding Machine

- Total 1

- Forming surface grinder Machine

- Total 1

- Internal Grinding Machine

- Total 1

- Optical Inspection Measuring Machine

- Total 8

- Two Lock Molding Machine

- Total 40

- Nut Tapper

- Total 10

- Header Machine

- Total 8

- Pinch Pointer

- Total 3

- Heat Treatment Machine

- Total 1

- Surface Grinding Machine

- Total 8

- Molding Grinding Machine

- Total 1

- Machining Center

- Total 2

- Automatic Programming Device

- Total 2

Inspection / Test Equipment

- Spring Tester Machine

- Total 1

- Profile Projector

- Total 1

- Contour Shape Measuring Machine

- Total 1

- Image Measuring Machine

- Total 4

- Microhardness Tester Machine

- Total 1

- Tension Compression Tester Machine

- Total 1

- Rockwell Hardness Tester Machine

- Total 1

- Salt Spray Tester Machine

- Total 1